High‑fat snacks and edible oils fight the same enemy: oxygen. Oxidation dulls color, produces off‑flavors, and shortens sellable life—driving waste, customer complaints, and line rework. Here’s the deal: it’s not enough to “add an antioxidant and hope.” If you work in QA, R&D, regulatory, or plant operations, you also need legally correct use levels, clean documentation, and a validation plan that survives audits. This guide walks through food antioxidants for shelf life from selection to proof: the regulations that govern them, the dosing and application patterns that actually work in fat‑rich matrices, and the QA workflows (PV, p‑AV, TOTOX, OSI/Rancimat) that convert data into confident shelf‑life statements.

You’ll find three quick‑reference tables (regulatory, dosing, and QA schedules), concise links to primary rules and methods, and practical notes on process integration and packaging. Use it to align R&D trials with regulatory limits, write ingredient lists correctly, and run stability studies that your customers and auditors can trust.

Oxidation 101 for High‑Fat Snacks and Oils

Oxidation is a chain reaction. Primary oxidation converts unsaturated lipids to hydroperoxides; secondary oxidation breaks those down into aldehydes and ketones that you can smell and taste. That’s why we track:

- Peroxide value (PV) for primary oxidation.

- p‑Anisidine value (p‑AV) for secondary oxidation.

- TOTOX as 2 × PV + p‑AV, a composite picture.

For accelerated stability, many labs use the Rancimat instrument to report Oxidative Stability Index (OSI) hours; higher OSI generally correlates with better shelf life, but you should always cross‑check with chemical and sensory data. Typical starting targets for refined oils entering packaging are PV ≤10 meq O2/kg and p‑AV ≤20, while the TOTOX trend should remain controlled over the declared shelf life. Exact acceptance criteria are product‑specific and must be tied to your own standards and customer requirements.

To make food antioxidants for shelf life deliver consistently, pair the chemistry (radical scavengers, chelators, synergists) with process decisions: oil turnover rates, fryer maintenance, seasoning oil management, oxygen and light control, and packaging design.

Regulatory Landscape You Can Audit

Formulators rarely get in trouble for choosing an antioxidant—problems arise when limits, categories, or labeling are off. Anchor your program to primary rules and keep links in your dossier.

- United States (FDA): Synthetic phenolic antioxidants BHA, BHT, and TBHQ are permitted as food preservatives under Title 21 CFR Part 172, generally limited so that the total in edible fats and oils doesn’t exceed 0.02% on a fat/oil basis. See the FDA’s consolidated “Food preservatives” subpart for section‑level details across BHA, BHT, and TBHQ in Part 172. Substances affirmed as GRAS (e.g., tocopherols, ascorbyl palmitate, citric acid; many rosemary extracts when standardized) are managed under Part 184 at levels consistent with good manufacturing practice. Ingredient labeling falls under Part 101. Authoritative anchors: the FDA’s current eCFR pages for Part 172 — Food preservatives (synthetic antioxidants), Part 184 — GRAS substances, and Part 101 — food labeling.

- European Union: Additives and maximum levels are established by Regulation (EC) No 1333/2008; consult the official Union List (Annex II) by food category. Antioxidants of interest include E319 (TBHQ), E320 (BHA), E321 (BHT), E306–E309 (tocopherols), E304 (ascorbyl palmitate), and E392 (rosemary extract). The overview of EU rules and the detailed category guidance for Annex II explain how to interpret categories for fats/oils and snacks. See the European Commission’s pages on EU additive rules and the Union List and the Annex II food category guidance (PDF).

- Codex (global reference): The GSFA tables provide internationally recognized provisions for edible fats and oils and related categories. Phenolic synthetics typically cap at 200 mg/kg on a fat/oil basis within individual limits, while many natural antioxidants operate at GMP. Always verify your exact product category in the current Codex database; a starting point is the Codex GSFA entry for edible fats and oils (02.3).

Below is a compact, non‑exhaustive quick reference. Always confirm the precise entry and category for your product.

| Antioxidant (common name) | US FDA (21 CFR) — typical provision | EU (Reg. 1333/2008) — indicative note | Codex GSFA — indicative note |

|---|---|---|---|

| TBHQ (tertiary‑butylhydroquinone) | Part 172: typically ≤0.02% of fat/oil in edible fats and oils; label by common name under Part 101 | E319 permitted by category; many fats/oils allow up to 200 mg/kg; confirm Annex II | Often MLs near 200 mg/kg in fats/oils categories; confirm table |

| BHA (butylated hydroxyanisole) | Part 172: typically ≤0.02% of fat/oil basis; combinations count toward total | E320, category‑specific MLs; confirm Union List | Similar fat/oil‑basis limits in GSFA categories |

| BHT (butylated hydroxytoluene) | Part 172: typically ≤0.02% of fat/oil basis | E321, category‑specific MLs; confirm Union List | Similar fat/oil‑basis limits in GSFA categories |

| Mixed tocopherols (vitamin E) | Part 184 GRAS at GMP; often declared as “mixed tocopherols (antioxidant)” | E306–E309 frequently quantum satis (GMP) by category | INS 307, many categories at GMP |

| Ascorbyl palmitate | Part 184 GRAS at GMP; synergist and antioxidant | E304 permitted by category; check MLs vs. QS | INS 304; many categories QS |

| Rosemary extract | Often GRAS‑based under Part 184 at GMP (standardized extracts) | E392 permitted by category; MLs vary by matrix | INS 392; many categories QS |

Tip: Keep a one‑page dossier with the exact citations relevant to your product. It saves hours when customers, auditors, or regulators ask “what’s your legal basis?”

Choosing the Right Food Antioxidants for Shelf Life

You don’t pick antioxidants in isolation; you design a system. In high‑fat snacks and edible oils, the best outcomes come from pairing a primary radical scavenger with a chelator/synergist and good process hygiene. Synthetics (TBHQ, BHA, BHT) are thermally robust and cost‑effective; natural options (mixed tocopherols, rosemary extract) offer cleaner labels with potency that depends on composition and matrix. Ascorbyl palmitate often boosts either family, and citric acid ties up trace metals that catalyze oxidation.

Thermal stability matters. TBHQ performs well in frying and high‑heat applications; tocopherols can degrade under sustained heat, so sequence and points of addition are key. Sensory is the other guardrail—some rosemary extracts and high tocopherol doses can affect flavor if overtuned.

Below is a practical, practice‑based quick card. Always align with the legal maxima for your category and verify potency with your own trials.

| Ingredient | Typical use range (fat/oil basis) | Functional notes | Labeling note |

|---|---|---|---|

| TBHQ | 50–200 mg/kg (0.005–0.02%) | Heat‑stable; strong in frying oils and snacks | “TBHQ” (antioxidant) per local rules |

| BHA | 50–100 mg/kg | Often paired with BHT/TBHQ; mind the combined cap | “BHA” per local rules |

| BHT | 50–100 mg/kg | Complements BHA; robust in fats/oils | “BHT” per local rules |

| Mixed tocopherols | 200–1000 mg/kg | Natural option; composition (γ/δ) drives potency | “Mixed tocopherols (antioxidant)” |

| Rosemary extract | 100–500 mg/kg | Natural; potency depends on carnosic acid/carnosol | “Rosemary extract (antioxidant)” |

| Ascorbyl palmitate | 50–200 mg/kg | Synergist; supports primary antioxidant | “Ascorbyl palmitate” |

| Citric acid / citrate | 10–100 mg/kg | Chelates metals; improves overall efficacy | “Citric acid” or “Sodium citrate” |

For deeper practice context, industry overviews summarize natural‑system tradeoffs and dosing considerations; see UL Prospector’s primer on natural antioxidants and shelf life in fats and oils. Use such secondary sources to shape trials, then confirm with your own data.

QA Workflows to Prove It

An antioxidant program is only as strong as its data trail. A practical workflow aligns sampling, methods, and acceptance criteria from pilot to launch. Core methods:

- PV by titration (AOCS Cd 8b‑90 or ISO 3960) for primary oxidation. ISO lists the recognized method under ISO 3960 — peroxide value.

- p‑AV by spectrophotometry (AOCS Cd 18‑90) for secondary oxidation.

- TOTOX = 2 × PV + p‑AV to summarize the picture.

- OSI (Rancimat) by AOCS Cd 12b‑92 for accelerated stability benchmarking (method cited in AOCS resources).

Below is a QA schedule you can adapt for oil refining, snack frying oil, and finished snacks.

| Phase | Matrix | Tests | Frequency | Illustrative acceptance targets |

|---|---|---|---|---|

| Incoming oil | Refined edible oil | PV, p‑AV; OSI (periodic) | Each lot; OSI quarterly | PV ≤10 meq/kg; p‑AV ≤20; OSI vs. spec |

| Process control | Fryer oil in use | PV trending; OSI (spot); sensory | Daily/shift | Trend stable; corrective action if slope accelerates |

| Finished product | High‑fat snack | PV (oil extract), p‑AV; sensory | Each batch | Within internal spec; no rancid notes |

| Stability (accel) | Snack + oil | PV/p‑AV weekly; OSI baseline | 40–60°C chamber | Acceptable TOTOX slope within claim window |

| Stability (real‑time) | Snack + oil | PV/p‑AV monthly; sensory | Storage at target conditions | Meets claim with margin |

Illustrative example (for explanation only, not product claims): Suppose your refined sunflower oil starts at PV 4 and p‑AV 8. You dose TBHQ at 120 mg/kg plus 50 mg/kg ascorbyl palmitate and 30 mg/kg citrate in the seasoning oil. Accelerated testing (45°C) shows PV rising by ~1.0 meq/kg per week and p‑AV by ~1.5 per week over 8 weeks. TOTOX goes from 16 to 36 in week 8. If your internal TOTOX threshold for acceptable flavor is 40 and real‑time data at ambient aligns with a 3× slower slope, you might support a 6‑month shelf‑life claim with conservative margin—provided sensory panels confirm no off‑notes and packaging oxygen levels stay within spec. The point isn’t the exact numbers, but the discipline: track PV, p‑AV, TOTOX, tie them to sensory, and document every step.

Related reading: for context on preservation strategies beyond antioxidants, see our concise overview of food preservatives and their roles in shelf life.

Process Integration and Packaging Controls

Antioxidants fight the fire; process prevents sparks. In snack and oil systems, you’ll get the most from food antioxidants for shelf life when you control oxygen and metals, limit thermal abuse, and design packaging to keep the headspace tight.

- Points of addition: For refined oils, add synthetics (e.g., TBHQ) upstream of high‑heat steps; for seasoning, dissolve or disperse antioxidants in the carrier oil and apply promptly to minimize oxygen pickup. Rosemary and tocopherols often perform better when added post‑refine, pre‑pack.

- Oil management: Track turnover and top‑off rates, skim polymers and crumbs, and filter appropriately. High dwell times increase oxidative load and can overwhelm any antioxidant system.

- Oxygen and light: Nitrogen‑flush snack packs; use barrier films tuned to shelf‑life targets; avoid clear bottles for light‑sensitive oils unless antioxidant load and turnover compensate.

- Metals and sanitation: Chelate trace iron/copper with citrate; maintain fryer and heat‑exchanger cleanliness; avoid brass/copper contact.

- Thermal profile: Keep frying temperatures in spec and avoid long hot‑hold periods for seasoned products.

Note: Some “natural color” carriers include phenolic components that contribute mild antioxidant effects. For a broader background on these ingredients as they relate to perception and stability, see our article discussing whether natural colors can replace artificial dyes in foods.

Procurement, COAs, and Audit Readiness

Regulatory rigor lives in your paperwork. Build a supplier and batch dossier that a third‑party auditor can follow without emailing your team for every detail. The essentials:

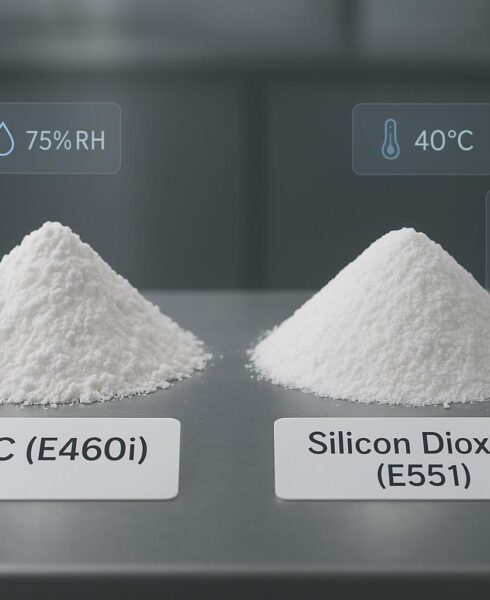

- COA & specs: Ingredient name and grade; INS/E‑number; CAS; assay/potency (e.g., TBHQ % or carnosic acid %); identity tests; heavy metals; residual solvents; loss on drying; particle size (if applicable); storage and retest date; allergens; country of origin; conformity to 21 CFR/Reg. 1333/2008/GSFA notes as applicable.

- Label language: Draft accurate ingredient statements for each market and product category; list the antioxidant by common name and, where appropriate, its function.

- Supplier qualification: Certifications (ISO, HACCP, Halal/Kosher, FCC alignment), change‑control policy, recall/traceability, and audit reports.

- Stability file: Your protocols, raw data, and interpreted charts for PV, p‑AV, TOTOX, OSI; sensory notes; packaging oxygen data; and sign‑offs.

Disclosure: Anrui Biotech is our product. In practice, a documentation‑forward bulk supplier such as Anrui Biotech can support procurement with ingredient COAs, specs, and export documentation for audit‑ready dossiers without making performance claims about your specific recipe.

If you need an example of how to structure short technical Q&A that lives well in customer portals, our general vitamins page provides a simple Q&A layout you can mirror for antioxidant documentation (different content, same structure).

FAQs for Regulatory‑Focused Teams

Q: Can I combine TBHQ with BHA/BHT? A: In the US, phenolic synthetics are typically capped so that the total in edible fats and oils doesn’t exceed 0.02% on a fat/oil basis under Part 172; combinations must respect both individual and total limits. In the EU and Codex, confirm category‑specific limits and any combination rules in the current tables.

Q: What does “quantum satis” or GMP actually mean for natural antioxidants? A: Use the minimum effective amount consistent with good manufacturing practice, subject to any category‑specific caps. You still need a rationale and data showing that amount is technologically justified.

Q: How do I validate a shelf‑life claim? A: Pair accelerated (e.g., 45–60°C) and real‑time studies. Track PV and p‑AV on a schedule, compute TOTOX, measure OSI at baseline and at defined intervals, and confirm with trained sensory. Document methods and acceptance criteria. Anchor methods to AOCS/ISO standards like Cd 18‑90 for p‑AV and ISO 3960 for PV. Keep external links in your dossier so auditors can verify with primary sources such as the EU’s Union List overview and guidance and the Codex GSFA category for edible fats and oils.

Methods and Sources You Should Cite in Your Dossier

- Regulatory anchors: FDA’s current eCFR on Part 172 Food preservatives, Part 184 GRAS, and Part 101 labeling; the European Commission’s Union List overview and Annex II guidance PDF; and the Codex GSFA edible fats and oils page.

- Methods anchors: AOCS Cd 18‑90 p‑anisidine method and ISO’s index for ISO 3960 peroxide value. These give auditors an immediate path to confirm your methods.

What to Do Next

- Align your target markets and product categories, then confirm the precise entries for each antioxidant in FDA, EU Annex II, and Codex tables.

- Build a pilot with two systems (e.g., TBHQ+AP+citrate vs. tocopherols+rosemary+AP) and a matched process plan; run PV/p‑AV/TOTOX and OSI from baseline.

- Lock your documentation: COAs and specs, label language per market, a stability protocol with acceptance criteria, and a clean chain of sign‑offs.

When you combine the right chemistry with good process control and a defensible QA program, food antioxidants for shelf life become a repeatable capability—not a guessing game.