Sodium alginate powder is a useful ingredient in food. Many companies use sodium alginate because it comes from nature. It also has a clean label and helps make food thicker. It can form stable gels and keep foods from separating. More people around the world are using sodium alginate powder. It is popular in dairy, candy, and plant-based foods. Alginate helps food last longer and lets chefs try new cooking ideas. It also protects ingredients that are easy to spoil. Many processed foods use alginate for its special features. These include making edible films, trapping flavors, and forming gels.

Key Takeaways

-

Sodium alginate powder is made from brown seaweed. It is safe and comes from plants. People use it a lot in food. It makes food thicker and more stable. It helps food form gels. This makes dairy, sauces, and desserts better. Chefs use sodium alginate in creative ways. They make small, tasty spheres with it. Sodium alginate gives extra fiber to food. This fiber helps with digestion. It can help you feel full. It is good for your gut health. It helps food last longer. It forms a natural film on food. This film keeps food from spoiling. It does not need fake chemicals.

Sodium Alginate Powder in the Food Industry

Natural Origin

Sodium alginate comes from brown seaweed. This seaweed grows in oceans all over the world. The cell walls of these plants have a lot of alginates. Companies get alginate from seaweeds like Laminaria, Macrocystis, Ascophyllum, and Sargassum. These seaweeds can have up to 40% alginate when dry.

To make sodium alginate powder, workers wash and dry the seaweed. Then, they grind it into a fine powder. Ethanol is used to take out color and fat. After that, acid is added to remove things that are not needed. This step makes alginate turn into alginic acid, which does not mix with water. Next, sodium carbonate is added. This changes alginic acid into sodium alginate, which can dissolve in water. The powder is filtered and washed again to make it pure. The end result is a fine, white powder.

Sodium alginate is a natural gelling agent. Its chemical structure has mannuronic and guluronic acid blocks. These blocks help control how alginate thickens and forms gels in food. The food industry likes sodium alginate because it is safe and comes from nature.

|

Aspect |

Details |

|---|---|

|

Source |

Brown seaweed (Laminaria, Macrocystis, Ascophyllum, Sargassum) |

|

Main Component |

Alginates in cell walls |

|

Extraction Steps |

Washing, grinding, ethanol treatment, acid and alkali steps, filtration |

|

Functional Role |

|

|

Annual Production |

Clean-Label Appeal

Many people want foods with simple and natural ingredients. They look for labels they can trust. Sodium alginate fits this need. It comes from seaweed, not from lab-made chemicals. The food industry uses sodium alginate in many products because it is safe and plant-based.

-

People who care about health pick foods with sodium alginate instead of fake additives.

-

Sodium alginate helps vegan and vegetarian foods taste and feel better.

-

The market for sodium alginate powder is getting bigger. In 2023, it was worth about $160 million. Experts think it will grow to $260 million by 2032.

-

More people want clean-label foods. They want to know where their food comes from and how it is made.

-

Sodium alginate helps make food in a way that is good for the planet. Seaweed grows fast and does not need much land or water.

Food makers like sodium alginate more than fake additives for many reasons:

-

It makes foods thicker, smoother, and more stable.

-

It helps companies use ingredients that are good for the earth.

-

It helps companies meet goals for clean labels and being open about ingredients.

The food industry uses alginate to make foods that people trust and enjoy. Sodium alginate is important in plant-based, dairy, and ready-to-eat foods. More people want healthy and natural foods, so the use of sodium alginate keeps growing.

Texture Enhancement

Dairy Applications

Dairy foods need help to stay smooth and tasty. Sodium alginate is important in many dairy products. Yogurt, cheese, and ice cream use this ingredient. In yogurt, alginate keeps whey from separating. This helps yogurt last longer and stay stable. Cheese makers use alginate to help cheese melt well. It also helps cheese hold more water. This makes cheese slices softer and stops whey from leaking. Ice cream makers add sodium alginate to stop ice crystals. This keeps ice cream creamy and smooth after storage.

|

Dairy Product |

Role of Sodium Alginate Powder in Texture Enhancement |

|---|---|

|

Yogurt |

Stops whey from separating, makes texture better, keeps yogurt stable and fresh longer |

|

Cheese |

Helps cheese melt, keeps moisture in, stops whey from leaking |

|

Ice Cream |

Stops ice crystals, makes texture better, slows melting |

|

Dairy-based sauces/dressings |

Makes sauces thicker, improves texture and consistency |

Sodium alginate forms a gel when it meets calcium in milk. This gel helps dairy foods keep their shape and texture. In ice cream, sodium alginate makes the mix thicker. This slows down ice crystal growth and keeps ice cream soft. The gel also holds water, so big ice crystals do not form. Many dairy recipes use sodium alginate for better quality.

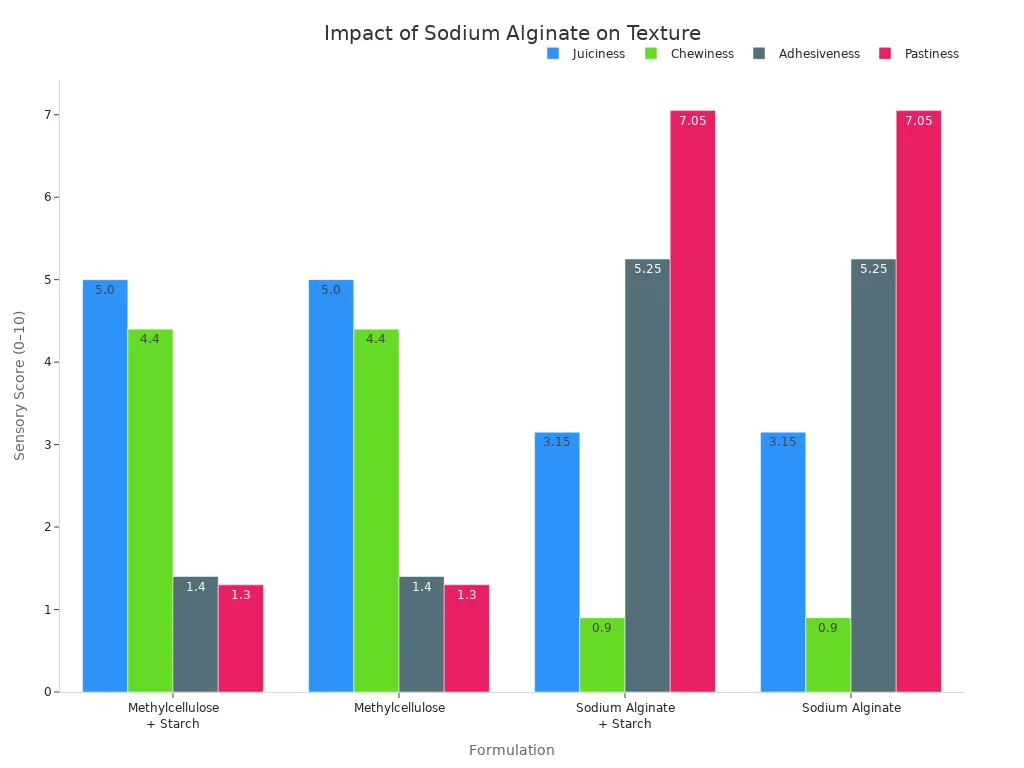

Sensory Experience

Alginate changes how foods feel and taste. It makes foods smoother and softer. In ice cream, sodium alginate makes it creamier and helps it melt slower. In yogurt and cheese, it gives a stable and nice mouthfeel. Taste tests show alginate makes foods stick together more. It also makes foods less chewy and less juicy. This means foods feel smoother and less crumbly.

People notice these changes in taste tests. Foods with alginate often score higher for smoothness. The gel-forming ability of sodium alginate helps make recipes with better texture. Many recipes use this feature to make foods more enjoyable. Chefs and food makers use alginate to improve the eating experience in many recipes.

Gelling & Thickening with Sodium Alginate

Controlled Viscosity

Sodium alginate lets food makers change how thick foods are. This powder comes from brown seaweed. It is a hydrocolloid. When you mix it with water, it makes a smooth liquid. It helps soups, sauces, and desserts get thicker. The powder mixes in well and does not make lumps. This means every part of the food feels the same.

The real change happens when calcium is added. Calcium sticks to the guluronic acid in alginate. This makes a strong gel network. The gel holds water and keeps food thick and stable. Using more or less sodium alginate changes how thick food feels. Most recipes use between 0.5% and 1.5% of the powder. Chefs often mix sodium alginate with other dry things first. This stops lumps from forming. The right amount makes food creamy, not rubbery.

Tip: Do not use too much heat when mixing sodium alginate. High heat can break the gel and change the food’s texture.

Stability in Sauces & Dressings

Sauces and dressings can separate or lose texture over time. Sodium alginate helps keep them mixed and smooth. It works as a thickener and a stabilizer. When you add it, alginate makes sauces thicker and stops water and oil from splitting. This keeps sauces and dressings creamy.

Alginate works in both hot and cold foods. It forms a gel that keeps its shape and holds in water. This helps sauces and dressings stay fresh for longer. Alginate likes water, so it keeps foods from drying out. Sometimes, alginate works with pectin to make sauces that can be heated and cooled without losing thickness.

Here are some ways sodium alginate is used in food:

-

It keeps whipped toppings, ice creams, and desserts stable.

-

It helps jellies, jams, and fruit sweets form gels.

-

It makes puddings and cold milk desserts feel better.

|

Food Product |

Role of Sodium Alginate |

|---|---|

|

Salad Dressing |

Thickener, stabilizer |

|

Tomato Sauce |

Viscosity control, gel former |

|

Pudding |

Gelling agent, texture boost |

|

Jam |

Gel formation, moisture hold |

Sodium alginate helps recipes stay thick and smooth. It keeps sauces and dressings from separating, even after a long time. This is why food makers like using alginate for high-quality foods.

Spherification and Culinary Innovation

Spheres in Modern Cuisine

Spherification has changed how chefs make food look. This method uses sodium alginate and calcium salts. It turns liquids into small balls that look like caviar. Chefs mix sodium alginate with a flavored liquid. They drip this mix into a bath with calcium chloride. The calcium reacts with the alginate. This makes a thin gel shell around each drop. The inside of the ball stays liquid. Chefs need to use the spheres soon. The shell gets thicker if they wait too long.

Direct spherification is used most often. Chefs mix sodium alginate with water. Then they add it to the recipe liquid. They drip this into the setting bath to make caviar-like beads. Reverse spherification is for liquids with lots of calcium. Chefs put calcium in the recipe liquid. Then they drop it into a sodium alginate bath. This makes bigger spheres. It works well for things like mango ravioli or melon soup balls.

Modern cooking uses spherification to make new textures and looks. Famous chefs like Ferran Adria and Heston Blumenthal made these spheres popular. They use them in molecular gastronomy. The spheres make dishes more fun and let chefs control when flavors come out. Spherification recipes use fruit juices, soups, or drinks. Chefs can serve the spheres cold or hot. They can even make them fizzy.

Tip: If the liquid is sour, add sodium citrate before spherification. This helps sodium alginate work better and keeps the spheres stable.

Encapsulation Techniques

Sodium alginate helps control how flavors come out in spheres. When sodium alginate meets calcium ions, it forms a gel network. This is called the “egg box” structure. The gel holds the liquid inside the sphere. It also controls how fast flavors escape. The gel’s strength and holes depend on how much alginate and calcium are used. Chefs can change these things to make flavors come out fast or slow.

|

Mechanism/Property |

Description |

Effect on Controlled Release |

|---|---|---|

|

Sodium alginate forms a 3D gel with calcium ions. |

Controls release by breaking down and spreading. |

|

|

Porosity and mechanical properties |

Alginate amount and G/M ratio change gel strength and holes. |

Changes how fast flavors come out and water soaks in. |

|

G/M ratio effect |

G-rich alginate makes hard, holey gels; M-rich makes soft gels. |

Changes how fast flavors come out and how stable the gel is. |

|

Calcium ion concentration |

More calcium makes more holes at first, then slows release. |

Changes gel strength and how flavors come out. |

|

Complex coacervation with chitosan |

Alginate and chitosan make a strong matrix for spheres. |

Makes spheres more stable and controls flavor release. |

|

Drying process |

Not drying all the way keeps the matrix whole. |

Keeps flavor release steady. |

Spherification lets chefs make spheres with different textures and tastes. These spheres can hold juice, sauce, or foam. The way flavors come out makes each bite special. Spherification with sodium alginate is now a big part of modern cooking. Chefs use these spheres to surprise people and make meals fun.

Health & Preservation Benefits

Dietary Fiber Contribution

Sodium alginate gives lots of dietary fiber to foods. This powder is mostly made of fiber. It helps people get enough fiber each day. For example, a drink with 9.9 grams of sodium alginate has about 6.3 grams of fiber. If you use 15 grams, you get 9.5 grams of fiber. These amounts show sodium alginate is high in fiber. Adding it to foods like pasta makes them have more fiber and a better feel.

Eating foods with sodium alginate helps you feel full longer. The fiber slows how fast your stomach empties. It also helps keep blood sugar from rising too quickly after eating. Studies say drinks with sodium alginate help lower hunger and control blood sugar and insulin. People who eat more fiber from sodium alginate may have lower cholesterol. Sodium alginate helps good gut bacteria and protects the gut lining. These things help stop some health problems and make your gut healthier.

Note: Sodium alginate does not give many vitamins or minerals. Its main health help comes from fiber and how it helps your digestion.

Shelf Life Extension

Sodium alginate helps food stay fresh for more time. It makes a thin, safe film on food surfaces. This film keeps out germs and slows down spoilage. When mixed with things like thymol or resveratrol, sodium alginate films stop bacteria and keep fats from spoiling. These films also stop food from drying out or turning brown.

Food makers use sodium alginate to protect meats, cheeses, and other foods that spoil fast. The film blocks oxygen and oil, which stops food from going bad and keeps it moist. Sodium alginate can carry extra things like essential oils or citric acid. These extras make the film even better at fighting bacteria. Tests show sodium alginate films with citric acid stop bad bacteria from growing on foods like ham during storage. This means food stays safe and tasty for more days.

Tip: Sodium alginate films are safe, break down naturally, and do not change food’s taste. They help food last longer without fake chemicals.

Sodium alginate helps the food industry in many ways. It makes foods thicker and helps them stay fresh. It also forms gels and keeps foods from separating. Alginate comes from seaweed, so it is natural and safe. This fits with the trend for clean labels. Chefs use alginate to make spheres and caviar shapes. These spheres can be found in desserts, drinks, and savory foods. Reverse spherification lets chefs make bigger spheres with liquid inside. Small caviar spheres give a pop of flavor in each bite. The food industry likes alginate because it helps make new and better foods. Experts think alginate and spheres will be important for future foods.

FAQ

What is sodium alginate powder made from?

Sodium alginate powder comes from brown seaweed. Factories take it out of seaweed that grows in the ocean. The powder is natural and safe for most foods.

Can sodium alginate powder be used in vegan recipes?

Yes, sodium alginate powder works in vegan recipes. It comes from plants, not animals. Many vegan foods use it to make texture and stability better.

Does sodium alginate powder change the taste of food?

Sodium alginate powder does not have much taste. It does not change how most foods taste. Chefs use it to change how food feels, not how it tastes.

How does sodium alginate help keep food fresh?

Sodium alginate makes a thin layer on food. This layer keeps germs out and slows down spoilage. It helps food stay moist and last longer.

Is sodium alginate powder safe to eat every day?

Most people can eat sodium alginate powder safely. It gives fiber to your diet. People with health problems should talk to a doctor before using it often.